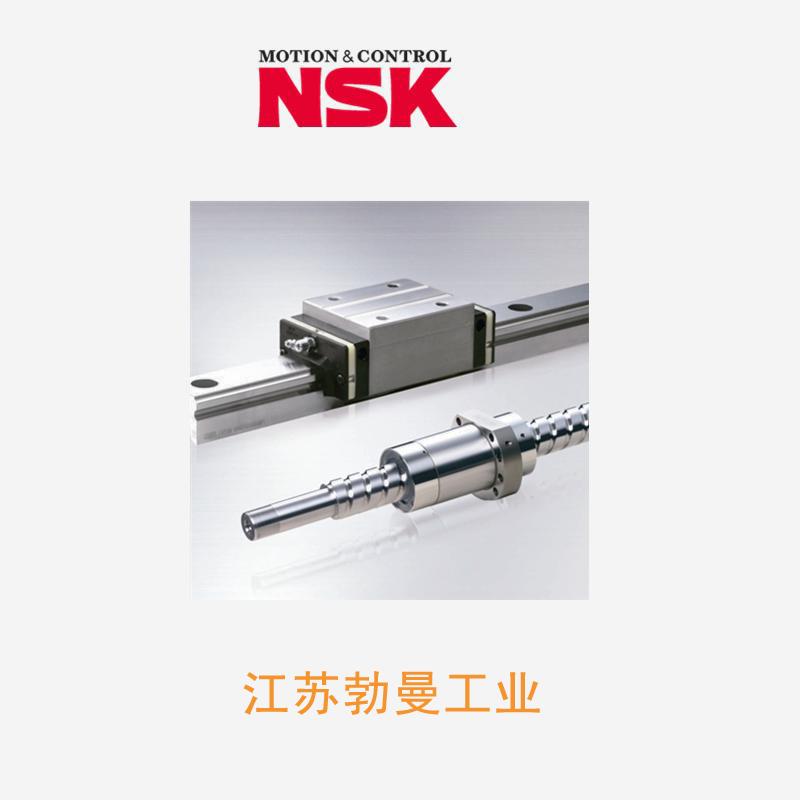

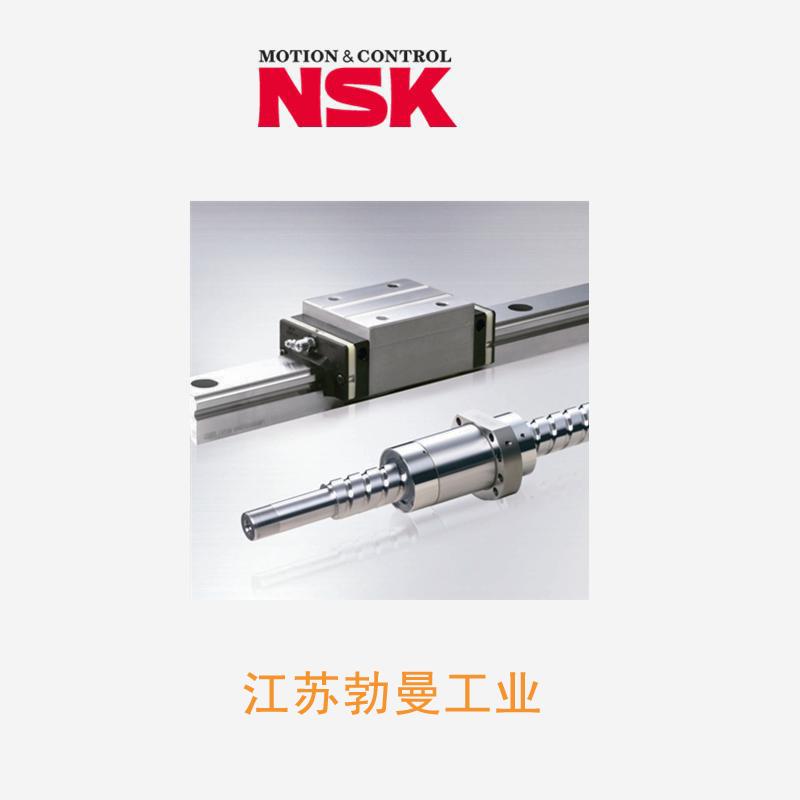

NSK W3206C-111PSS-C5Z-BB nsk丝杠ma系列

扫码获取价格库存技术资料

扫码获取价格库存技术资料

- 品牌:

- 分类:

- 类型:

- 属性: NSK W3206C-111PSS-C5Z-BB nsk丝杠ma系列,-NSK W3206C-111PSS-C5Z-BB nsk丝杠ma系列-NSK W3206C-111PSS-C5Z-BB NSK滚珠丝杠中国沈阳产地 NSK1208滚珠丝杠采用优质的材料制造,具有良好的耐磨性和耐腐蚀性,使其能够在恶劣的工作环境中正常运行。其精密的制造工艺和严格的质量控制保证了其高品质和可靠性。 NSK W3206C-111PSS-C5Z-BB 陕西nsk滚珠丝杠厂家 此外,北京NSK滚珠丝杠具有较高的精度和可靠性。它的精度可以达到几乎没有摆动,可以满-NSK W3206C-111PSS-C5Z-BB nsk丝杠ma系列--NSK W3206C-111PSS-C5Z-BB nsk丝杠ma系列-